-

PRODUCTS

-

-

-

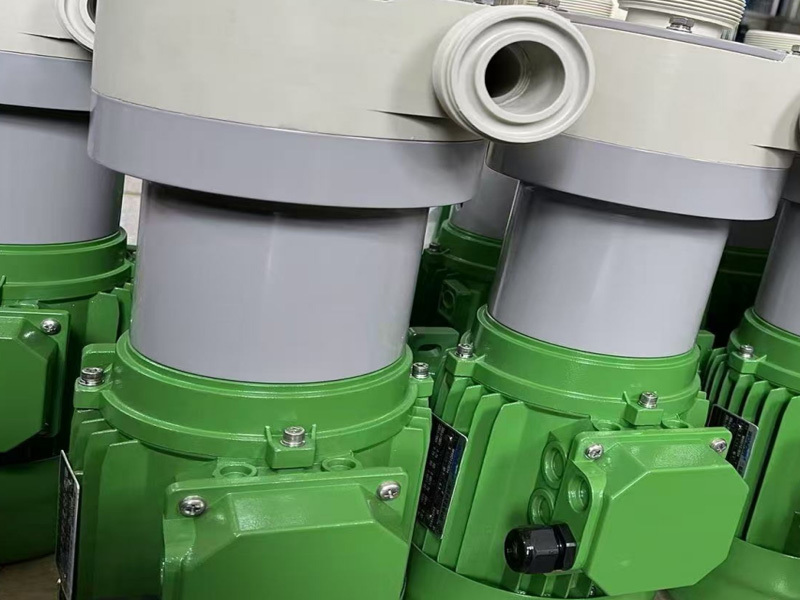

MPN magnetic application

Nov 29,2024

Magnetic force is widely utilized in various applications in our daily lives. A significant aspect of magnetism is its applicability to practical purposes, such as in the field of magnetic particle inspection (MPI). In this article, we will explore the diverse applications of magnetism in MPI and how it is revolutionizing the way we detect flaws and inspect materials.

MPI, also known as magnetic particle inspection, is a non-destructive testing method used to detect surface and near-surface flaws in ferromagnetic materials. The principle of MPI is based on the interaction between a magnetic field and magnetic particles. When a magnetic field is applied to a ferromagnetic material, the magnetic particles align along the magnetic lines of force, forming a pattern that can reveal any defects present in the material.

A common application of MPI is in the inspection of welds. Welding is a crucial process in many industries, such as construction, manufacturing, and aerospace. Ensuring the quality of welds is critical to preventing structural failures and ensuring the safety of finished products. By applying magnetic particles to the surface of a weld and observing the magnetic pattern formed, MPI can be used to detect defects in welds, such as cracks, porosity, and lack of fusion.

Another application of MPI is in the inspection of components in the automotive industry. With the increasing demand for lighter and more fuel-efficient vehicles, manufacturers are turning to advanced materials such as high-strength steel and aluminum alloys. MPI can be used to detect defects in these materials, such as stress corrosion cracking, fatigue cracks, and material degradation, ensuring the safety and reliability of automotive components.

In the aerospace industry, MPI is used to inspect critical components such as turbine blades, landing gear, and structural components. These components are subjected to extreme conditions such as high temperatures, pressures, and vibrations, making them susceptible to defects that could compromise their integrity. MPI can detect defects such as surface cracks, corrosion, and material degradation, allowing for timely repair and maintenance to prevent catastrophic failures.

The oil and gas industry also relies on MPI for the inspection of pipelines, storage tanks, and pressure vessels. These components are exposed to harsh environments such as corrosive chemicals, high pressures, and temperature fluctuations, which can lead to material degradation and defects. MPI can detect defects such as stress corrosion cracking, pitting, and weld defects, ensuring the integrity and safety of oil and gas infrastructure.

In conclusion, MPI is a valuable tool for detecting flaws and inspecting materials across various industries. By leveraging the power of magnetism, MPI can detect defects invisible to the naked eye, allowing for timely repair and maintenance to ensure the safety and reliability of critical components. As technology continues to advance, the applications of MPI will only increase, further revolutionizing the way we inspect materials and ensure quality in our daily lives.

PREVIOUS:

Contact Us

E-mail :

honking@139.com

Phone/WhatsApp:

+86-13833932888

Address:

Workshop 601, Building 1, LIANDO U Valley, Hexie Road 27, Sino-Korean Industrial Park, Zhongkai, Huizhou, Guangdong, China

Export Manager: Ms. Zhou

No. 601, Liandong U Valley 1, No. 27, Hexi Road, Zhongkai District, Huizhou City, China-Korea Huizhou Industrial Park Start-up Zone

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Request Quote